GEO SMART Control Panel for 2 to 4 motor pumps is a single control panel for multiple applications, such as: Emptying, Filling and Pressurisation. The GEO SMART can be used as a general control panel or a remote control functioning panel.

Electronic control panel with microprocessor available in single or three phase version, equipped with electronic protection against dry running and integrated pump exchanger.

Easy to install and start thanks to motor current and cosφ self-calibration.

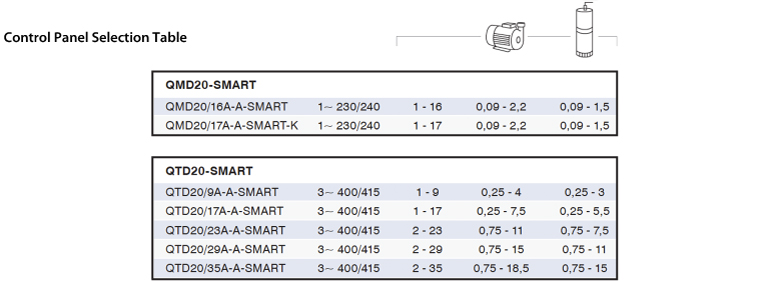

It is suitable for surface pumps, submersible pumps and motors in general, with power range between 0,09 kW and 18,5 kW (please download the data sheet to learn more about all the available sizes and features). It can be used for emptying, filling and pressurization.

Electronic control panel with thermoplastic case and IP55 protection degree

- Applications: Emptying, Filling, Pressurisation

- Single and Three phase

- Rated current from 1 to 200A

- All types of startup

- Self learning

- Motor Start and stop buttons

- Status display motors and equipment

- Electronic protection motor current

- Electronic protection against dry running, with no probes

- Automatic control for frequent starts

- Inputs probes for minimum/maximum level (self-learning of probe assembly)

- Protection control phase sequence (optional)

- Serial and contact communication for remote management (optional)

Inputs and outputs

- N. 4-7 (according to the model) inputs for floats or pressure switches;

- N. 1-4 (according to the model) inputs with double galvanic insulation for motor temperature probes (PTC, N.C.);

- Alarm output relay with changeover contact N.O. / N.C. (250V~ 5A max, resistive load);

Functions

- Command with buttons and LEDs;

- Preset modes for emptying, filling, pressurization (selectable);

- Selector for stop input operation mode (emptying or filling);

- Self-hold (excludable): operation in emptying or filling mode with separeted start and stop floats;

- Alternated pumps start and forced exchange for 12 hours continuous run of the same pump (excludable);

- Periodical unlock of the impeller (excludable);

- Second and following pumps start on-delay 4s;

- Alarm signal for dry running and stop level or pressure (excludable);

- Pumps control through maximum level or maximum pressure alarm input (selectable);

- Floats and pressure switches operation self diagnosis;

- Starting mode of one or more pumps for floats or command pressure switches intervention (selectable);

- Non contemporaneous pumps start and stop;

- 10s start on-delay after power supply restoration;

- Main disconnecting switch with door lock;

- Single phase motor starting capacitor, only in QMD10/17A-A-SMART-K model (suggested for frequent starting);

Protections

- Adjustable electronic protection for motor overload, on 2 phases (only for QTD10-SMART-S and QTD20-SMART models);

- Protection for minimum load, unbalanced load, stuck contactor (excludable);

- Electronic protection against dry running (excludable, selectable threshold and mode);

- Maximum start per hour (excludable);

- Motor supply and auxiliary circuit protection fuses;

- Contactor command circuit voltage as power supply (only for QTD10-SMART-S and QTD20-SMART models);

- Very low voltage inputs;

Optional features

KCC – Running capacitor predisposition 12,5/16/20/25/30/35/40/45/50/60/70/75/80 μF (only for QMD10-SMART and QMD20-SMART models);

MCL – Electronic module for level control with probes (probes not included);

CSFI – Phases presence and phases sequence control module (only for QTD10-SMART-S e QTD20-SMART models);

SAL – Integrated acoustic and visual alarm;

M485 – Modbus-RTU RS-485 communication;